Truck Body Parts Names With Pictures: An Illustrated Guide to Understanding Your Rig typestruckssale.com

Understanding the anatomy of a truck is paramount for anyone who owns, operates, maintains, or even just admires these powerful machines. From the sleek lines of a pickup to the robust structure of a semi-truck, each component plays a vital role in its functionality, safety, and overall performance. This comprehensive guide, "Truck Body Parts Names With Pictures," aims to demystify the various external and structural elements of trucks, providing a clear, section-by-section breakdown. While actual images cannot be embedded, we will meticulously describe each part, allowing you to visualize its appearance and comprehend its function, much like a detailed diagram. Knowing these parts is not just for mechanics; it empowers owners to make informed decisions about maintenance, repairs, upgrades, and even safe operation, ultimately contributing to the longevity and efficiency of their valuable asset.

Truck Body Parts Names With Pictures: An Illustrated Guide to Understanding Your Rig

I. The Foundation: Chassis and Frame Components

At the very core of any truck lies its chassis, the skeletal framework upon which all other components are mounted. It’s the backbone that provides structural integrity and supports the vehicle’s weight.

- Frame Rails: These are the primary structural beams, typically two long, parallel steel or aluminum members that run the length of the truck. They are the main load-bearing elements.

[Image: Illustration of a ladder frame chassis, clearly showing the two parallel frame rails]

- Crossmembers: Shorter beams that connect the two frame rails horizontally, providing rigidity and preventing twisting. They are strategically placed to support engine, transmission, and body mounts.

[Image: Close-up of crossmembers bolted or riveted between frame rails]

- Axles (Front & Rear): Solid shafts or housings that connect the wheels. The front axle typically houses steering components, while the rear axle (or axles for multi-axle trucks) transmits power to the drive wheels.

[Image: Diagram showing front and rear axles with wheels attached]

- Suspension Components: The system that connects the vehicle to its wheels, allowing relative motion between the two. Key parts include:

- Leaf Springs: Layers of spring steel bowed together, commonly found in heavy-duty trucks. They flex to absorb shocks.

[Image: A typical leaf spring assembly mounted on an axle]

- Coil Springs: Helical springs used in lighter trucks and some front suspensions for a smoother ride.

[Image: A coil spring over a shock absorber]

- Air Bags (Air Suspension): Inflatable rubber bags that use compressed air to support the load, offering adjustable ride height and superior ride comfort, especially in commercial trucks.

[Image: An air bag suspension system showing the air bag, compressor, and lines]

- Shock Absorbers/Dampers: Devices that dampen spring oscillations, controlling vehicle bounce and improving handling.

[Image: A cutaway view of a shock absorber]

- Leaf Springs: Layers of spring steel bowed together, commonly found in heavy-duty trucks. They flex to absorb shocks.

- Wheels: The assemblies that tires are mounted on, connecting the truck to the ground. Typically made of steel or aluminum.

[Image: Various truck wheel designs (steel, aluminum dually)]

- Tires: The rubber components that provide traction, absorb minor road irregularities, and support the vehicle’s weight.

[Image: A range of truck tires (all-terrain, highway, mud-terrain, commercial truck tires)]

II. The Cab: Driver’s Command Center

The cab is the enclosed compartment where the driver operates the truck. It’s designed for safety, visibility, and comfort.

- Hood (Bonnet): The hinged cover over the engine compartment, providing access for maintenance and repairs.

[Image: A truck with its hood open, revealing the engine]

- Grille: The front-facing element, usually made of chrome or plastic, that allows air to flow into the radiator for cooling and protects it from debris. It also contributes significantly to the truck’s aesthetic.

[Image: A prominent truck grille with headlights]

- Headlights: Front-mounted lights that illuminate the road ahead, essential for night driving and visibility.

[Image: Modern truck headlights with LED elements]

- Bumper (Front & Rear): Protective bars at the front and rear of the vehicle, designed to absorb impact in low-speed collisions and reduce damage.

[Image: A heavy-duty truck front bumper with fog lights]

- Windshield: The large front window, typically made of laminated safety glass, providing clear visibility for the driver.

[Image: A truck cab showing the large windshield]

- Side Mirrors: Mounted on the exterior of the doors, providing rearward and side visibility, crucial for lane changes and backing up. Many are large and extendable for towing.

[Image: A large tow mirror on a truck door]

- Doors: Hinged panels that provide access to the cab, usually equipped with windows and locks.

[Image: A truck door, open, showing the interior panel]

- Fenders (Wheel Arches): The body panels that arch over the wheels, protecting the engine and passengers from mud, rocks, and other road debris thrown up by the tires.

[Image: A truck's front fender clearly visible above the wheel]

- Sleeper Cab: An extended portion of the cab, typically behind the driver’s seat in commercial trucks, providing a living space with a bed for long-haul drivers.

[Image: A semi-truck with an integrated sleeper cab]

III. The Business End: Cargo Area and Specialized Bodies

The rear section of a truck is where its primary function often lies – carrying cargo. The design varies widely depending on the truck’s intended use.

- Truck Bed (Pickup Truck): The open cargo area at the rear of a pickup truck, enclosed by side walls and a tailgate.

[Image: A standard pickup truck bed with the tailgate down]

- Tailgate: The hinged door at the rear of a pickup truck bed, allowing for easy loading and unloading of cargo.

[Image: A close-up of a truck tailgate]

- Flatbed: A completely flat, open cargo area without sides or a roof, ideal for transporting oversized or oddly shaped items.

[Image: A flatbed truck loaded with lumber]

- Dump Body: A hydraulically operated open-box bed that can be tilted to dump loose materials like sand, gravel, or dirt.

[Image: A dump truck with its bed raised in the dumping position]

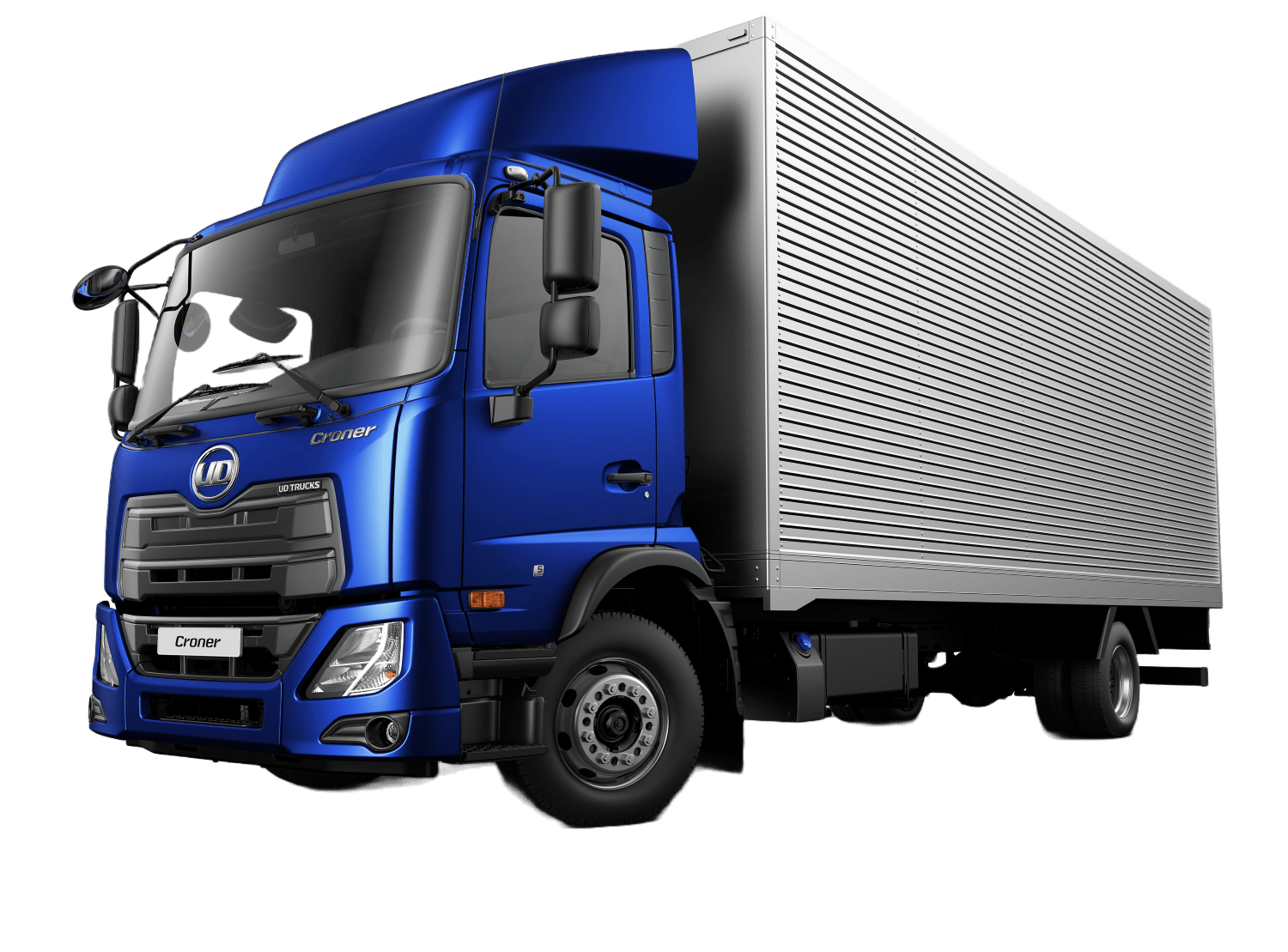

- Box Body (Dry Van/Refrigerated): An enclosed, rectangular cargo area, often mounted on a straight truck chassis. Dry vans protect goods from weather, while refrigerated (reefer) units maintain specific temperatures.

[Image: A large box truck (dry van) on the road]

- Tanker Body: A cylindrical or elliptical tank designed to transport liquids (fuel, water, chemicals) or gases.

[Image: A tanker truck transporting fuel]

- Rollback/Tow Body: A specialized flatbed that can hydraulically tilt and slide back to load and transport disabled vehicles.

[Image: A rollback tow truck with a car on its bed]

- Stake Body: A flatbed with removable vertical stakes along the sides, allowing for flexible cargo containment.

[Image: A stake body truck with stakes in place]

IV. Essential External Accessories and Safety Components

Beyond the main structural and functional components, several other external parts contribute to a truck’s operation, safety, and convenience.

- Fuel Tanks: Large reservoirs typically mounted on the side of the chassis, designed to hold the truck’s fuel supply.

[Image: A polished chrome fuel tank on a semi-truck]

- Exhaust System: A series of pipes, mufflers, and catalytic converters (for emissions control) that direct exhaust gases away from the engine. Often visible along the side or rear of the truck.

[Image: Large vertical exhaust stacks on a semi-truck]

- Mud Flaps (Splash Guards): Flexible flaps located behind the wheels to prevent mud, water, and debris from being sprayed onto other vehicles or pedestrians.

[Image: A truck with large rubber mud flaps]

- Fifth Wheel (for Semi-Trucks): A coupling device mounted on the tractor’s frame that allows a semi-trailer to be attached and pivoted, enabling the articulation of the rig.

[Image: A close-up of a fifth wheel coupling on a semi-truck tractor]

- Tail Lights/Brake Lights: Rear-mounted lights that indicate the truck’s presence and illuminate when brakes are applied, signaling deceleration to following vehicles.

[Image: A set of truck tail lights illuminating]

- Marker Lights: Small lights, often amber or red, placed along the sides and top of larger trucks and trailers to indicate their dimensions, especially at night.

[Image: A line of small marker lights along the side of a trailer]

- Steps/Running Boards: Platforms mounted below the doors to assist in entering and exiting the cab, especially in trucks with high ground clearance.

[Image: A truck with chrome running boards]

- Toolboxes: Storage compartments, often mounted on the side or within the truck bed, for carrying tools and equipment.

[Image: An aluminum toolbox mounted in a pickup truck bed]

V. Understanding Material and Maintenance Considerations

The choice of materials for truck body parts significantly impacts their durability, weight, and cost. Common materials include:

- Steel: The most common and robust material, offering high strength and affordability. However, it’s heavy and susceptible to rust.

- Aluminum: Lighter than steel, improving fuel efficiency and payload capacity. It’s also rust-resistant but generally more expensive and can be harder to repair.

- Fiberglass/Composites: Lightweight and can be molded into complex shapes, often used for fenders, hoods, and custom body panels. Less durable than metal against impact but resistant to corrosion.

Practical Maintenance Advice:

Regular inspection and maintenance of truck body parts are crucial for safety, appearance, and resale value.

- Regular Cleaning: Wash your truck frequently, especially after driving in salty conditions or off-road, to prevent rust and corrosion.

- Rust Prevention: Address any paint chips or scratches promptly to prevent rust from forming. Consider rust-proofing treatments for the undercarriage.

- Panel Alignment: Check doors, hood, and tailgate for proper alignment. Misalignment can lead to premature wear or water leaks.

- Lighting Check: Regularly test all headlights, tail lights, brake lights, and marker lights for proper function.

- Fluid Leaks: Inspect for any fluid leaks around the engine or transmission, which could indicate underlying issues.

- Tire Health: Monitor tire pressure and tread depth. Rotate tires as recommended.

Practical Advice and Actionable Insights

Understanding truck body parts isn’t just an academic exercise; it has tangible benefits for every truck owner and operator.

- Informed Maintenance and Repair: Knowing the names and functions of parts allows you to accurately describe issues to mechanics, understand repair estimates, and even perform minor fixes yourself.

- Safety Awareness: Recognizing damaged components like a cracked frame rail, loose bumper, or non-functional lights enables you to address safety hazards before they lead to accidents.

- Smart Buying/Selling: When purchasing a used truck, knowledge of body parts helps you identify potential damage or hidden issues. When selling, you can articulate the value of well-maintained components.

- Customization and Upgrades: If you plan to customize your truck (e.g., adding a lift kit, new bumper, or custom bed liner), knowing the relevant parts is essential for compatibility and proper installation.

- Cost Savings: Proactive inspection and early detection of wear or damage can prevent minor issues from escalating into expensive repairs.

Actionable Tip: Conduct a visual walk-around inspection of your truck at least once a week. Look for anything out of place, loose, or damaged. Pay attention to lights, tires, fluid leaks, and any unusual sounds.

Conclusion

The world of truck body parts is vast and intricate, but by breaking it down into manageable sections, we hope this guide has provided you with a clear and comprehensive understanding. From the foundational frame that bears the load to the specialized bodies that define its purpose, each part is a testament to the engineering marvel that is a truck. Equipping yourself with this knowledge empowers you to be a more responsible, safer, and more efficient truck owner or operator. Regular inspection, timely maintenance, and a keen eye for detail will ensure your rig not only looks its best but also performs reliably for years to come, keeping you and your cargo safely on the road.

Truck Body Parts Estimated Price Guide

Please note: The prices listed below are estimated ranges in USD and can vary significantly based on the truck’s make, model, year, part quality (OEM, aftermarket, used), supplier, and geographical location. These are for illustrative purposes only.

| Part Name | Description | Estimated Price Range (USD) | Common Materials | Notes |

|---|---|---|---|---|

| Chassis & Frame | ||||

| Frame Rail (Section) | Main structural beam, often replaced in sections. | $500 – $3,000+ | Steel | Replacement often requires professional welding/riveting. |

| Crossmember | Horizontal brace connecting frame rails. | $100 – $500 | Steel | Critical for structural rigidity. |

| Leaf Spring (Single) | Spring steel layers for suspension. | $150 – $600 | Spring Steel | Varies by number of leaves and load capacity. |

| Air Bag (Suspension) | Inflatable rubber bag for air suspension. | $200 – $800 | Rubber, Composite | Specific to air suspension systems. |

| Shock Absorber | Dampens spring oscillations. | $50 – $300 | Steel, Oil | Replace in pairs for balanced performance. |

| Wheel (Single) | Holds tire, connects to axle. | $100 – $800 | Steel, Aluminum | Aluminum wheels are typically more expensive. |

| Tire (Single) | Rubber component for traction. | $150 – $1,000+ | Rubber | Price varies by size, type (all-terrain, highway), and brand. |

| Cab Components | ||||

| Hood | Engine compartment cover. | $300 – $2,000 | Steel, Aluminum, Fiberglass | Can be painted or unpainted. |

| Grille | Front air intake, aesthetic element. | $100 – $1,000 | Plastic, Chrome, Steel | Often includes emblem. |

| Headlight Assembly | Full light unit (housing, bulb, lens). | $100 – $800 (per side) | Plastic, Glass, LED | LED/HID units are significantly more expensive. |

| Bumper (Front/Rear) | Impact absorption. | $200 – $1,500+ | Steel, Chrome, Plastic | Heavy-duty/aftermarket bumpers can be much higher. |

| Windshield | Front viewing window. | $200 – $800 | Laminated Glass | Installation costs are often separate. |

| Side Mirror (Complete) | Rearview mirror assembly. | $50 – $500 (per side) | Plastic, Glass, Metal | Power, heated, or tow mirrors are at the higher end. |

| Door Shell | Outer panel of the door. | $300 – $1,500 (per side) | Steel, Aluminum | Does not include internal components (window, lock). |

| Fender (Front) | Panel over front wheel. | $100 – $600 (per side) | Steel, Plastic, Fiberglass | Can be painted or unpainted. |

| Cargo & External | ||||

| Pickup Truck Bed | Rear cargo box (new replacement). | $1,500 – $5,000+ | Steel, Aluminum | Used beds can be found for less. |

| Tailgate | Hinged rear door of pickup bed. | $200 – $1,200 | Steel, Aluminum | With or without step/camera cutout. |

| Fuel Tank | Fuel storage. | $200 – $1,000 | Steel, Aluminum, Plastic | Capacity and material affect price. |

| Muffler (Exhaust) | Sound dampening part of exhaust. | $50 – $400 | Steel | Part of the entire exhaust system. |

| Mud Flap | Splash guard behind wheels. | $10 – $100 (per pair) | Rubber, Plastic | Branded or custom mud flaps can be more expensive. |

| Fifth Wheel Coupling | For connecting semi-trailer. | $1,000 – $5,000+ | Steel | Complex mechanical component for heavy-duty trucks. |

| Tail Light Assembly | Rear lights (brake, running, turn). | $50 – $400 (per side) | Plastic, LED | LED assemblies are typically higher priced. |

| Running Boards/Steps | Side steps for cab access. | $100 – $1,000+ | Aluminum, Steel, Plastic | Can be fixed, power-retractable, or custom. |

| Toolbox (Bed/Side Mount) | Storage compartment. | $100 – $800+ | Aluminum, Steel | Varies by size, material, and features. |

Frequently Asked Questions (FAQ)

Q1: Why is it important to know the names of truck body parts?

A1: Knowing the names of truck body parts is crucial for several reasons: it helps you accurately communicate issues to mechanics, understand repair estimates, identify potential safety hazards, make informed decisions when buying or selling, and perform basic maintenance or customization tasks yourself. It empowers you as a truck owner.

Q2: Where can I find replacement truck body parts?

A2: You can find replacement parts from several sources:

- Dealerships: Offer original equipment manufacturer (OEM) parts, which guarantee fit and quality but are often the most expensive.

- Aftermarket Retailers: Companies like AutoZone, Advance Auto Parts, or online stores (RockAuto, PartsGeek) offer aftermarket parts, which can be more affordable and vary in quality.

- Salvage Yards/Junkyards: A good source for used OEM parts, often at a significant discount.

- Online Marketplaces: eBay, Amazon, and specialized truck parts websites.

Q3: How often should I inspect my truck’s body parts?

A3: For optimal safety and longevity, you should perform a basic visual inspection of your truck’s exterior and key body parts at least once a week. This includes checking lights, tires, fluid leaks, and any visible damage. A more thorough inspection, including the undercarriage and suspension components, should be done during routine maintenance or at least every few months.

Q4: What’s the difference between OEM and aftermarket truck body parts?

A4:

- OEM (Original Equipment Manufacturer) Parts: These are parts made by the original manufacturer of your truck or by a company contracted by them. They are designed to fit perfectly and meet the exact specifications of your vehicle. They typically come with a warranty and are often more expensive.

- Aftermarket Parts: These are parts manufactured by companies other than the original truck maker. They can range widely in quality and price. Some aftermarket parts are equivalent to OEM, while others may be of lower quality or designed for performance upgrades. They often offer more affordable options.

Q5: Can I replace truck body parts myself, or do I need a professional?

A5: It depends on the part and your skill level.

- DIY-Friendly: Simple parts like headlights, tail lights, side mirrors (non-power), mud flaps, or even basic bumpers can often be replaced with common tools and some mechanical aptitude.

- Professional Required/Recommended: More complex parts like frame rails, extensive body panel replacements (e.g., doors, fenders that require painting and alignment), windshields, or suspension components (especially those involving heavy lifting or specialized tools) are best left to experienced mechanics or body shops. Safety is paramount when working with heavy vehicle components.