Reach Truck Test Questions And Answers: Your Ultimate Guide to Certification typestruckssale.com

In the bustling world of logistics and warehousing, the reach truck stands as a crucial piece of equipment, enabling operators to navigate narrow aisles and retrieve goods from towering heights with remarkable precision. Its unique design, which allows the mast and forks to extend forward beyond the outriggers, makes it indispensable for optimizing storage space. However, operating such a specialized machine demands a high level of skill, knowledge, and adherence to stringent safety protocols. This is where comprehensive training and certification, culminating in a rigorous reach truck test, become paramount.

This article serves as your definitive guide to understanding the "Reach Truck Test Questions And Answers." It’s designed not just to help you pass the test, but to truly comprehend the principles of safe and efficient reach truck operation, ensuring you become a confident and competent operator.

Reach Truck Test Questions And Answers: Your Ultimate Guide to Certification

Understanding the Reach Truck and Its Operations

A reach truck is a class II industrial truck primarily used for stacking and retrieving pallets in high-density storage environments. Unlike a counterbalance forklift, which carries the load entirely in front, a reach truck uses a "reach" mechanism that extends the forks out from the body of the truck, allowing it to pick up and place loads directly into racking. Stability is maintained by outriggers that extend forward, with the load typically positioned within the footprint of the truck for travel.

Key operational aspects include:

- Narrow Aisle Maneuverability: Designed for aisles often less than 10 feet wide.

- High Lift Capabilities: Can often lift loads to heights exceeding 30 feet.

- Precision Handling: Requires delicate control for accurate load placement.

- Pre-Shift Checks: Absolutely critical for identifying potential faults before operation.

The importance of thorough testing cannot be overstated. It ensures that operators are not only proficient in handling the machinery but also deeply knowledgeable about safety regulations, load dynamics, and emergency procedures, thereby minimizing the risk of accidents, injuries, and property damage.

The Structure of a Reach Truck Test

Reach truck certification tests typically consist of two main components:

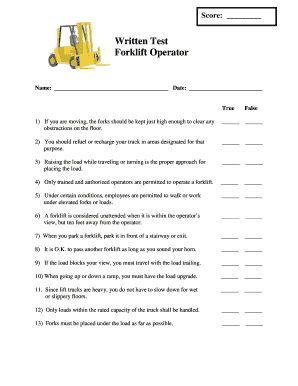

- Written (Theory) Examination: This section assesses your understanding of the reach truck’s components, safety regulations, operational principles, load capacity, stability, and emergency procedures. It’s designed to ensure you possess the foundational knowledge required for safe operation.

- Practical (Operating) Examination: This hands-on component evaluates your ability to perform various tasks safely and efficiently. It covers pre-shift inspections, maneuvering in confined spaces, picking up and placing loads at various heights, proper parking, and responding to simulated scenarios.

Both sections are critical, as a strong theoretical understanding informs safe practical application.

Common Written Test Questions and Answers (Theory)

Preparing for the written test requires a solid grasp of fundamental concepts. Here are common questions you might encounter, along with their expected answers:

A. Safety Regulations & Legislation

- Q: What is the primary role of regulatory bodies (e.g., OSHA in the US, HSE in the UK) regarding forklift operation?

- A: Their primary role is to set and enforce safety standards, ensuring a safe working environment and preventing workplace injuries and fatalities related to powered industrial trucks. They mandate training and certification.

- Q: How often is reach truck operator re-certification typically required?

- A: Generally, re-certification is required every three years, or sooner if there’s an accident, a near-miss, an evaluation indicates unsafe operation, or new equipment/work conditions are introduced.

- Q: What does a "red tag" on a reach truck or other powered industrial truck signify?

- A: A "red tag" indicates that the equipment is unsafe to operate and must not be used until repaired and re-inspected by a qualified person. It’s a critical safety warning.

- Q: Is it permissible to carry passengers on a reach truck?

- A: No, never. Reach trucks are designed for a single operator only, unless specifically designed with an approved passenger seat.

B. Reach Truck Components & Functions

- Q: What is the purpose of the outriggers on a reach truck?

- A: Outriggers extend forward from the truck’s body and serve as stabilizing supports, distributing the load’s weight and increasing the truck’s stability, especially when the mast is extended or loads are elevated.

- Q: How does the "reach" mechanism on a reach truck operate?

- A: The reach mechanism allows the mast and forks to extend forward and retract, enabling the operator to pick up and place loads deep into racking or close to the truck’s body for travel.

- Q: Define "load capacity" and explain its importance.

- A: Load capacity is the maximum weight a reach truck can safely lift at a specified load center. It’s crucial because exceeding it can lead to instability, tip-overs, and structural damage to the truck or racking. Always consult the data plate.

- Q: What is "load center" and why is it significant?

- A: Load center is the horizontal distance from the vertical face of the forks to the load’s center of gravity. It’s significant because as the load center increases (e.g., handling longer loads), the effective load capacity of the truck decreases, impacting stability.

C. Operational Procedures

- Q: Why is a pre-shift inspection crucial, and what does it typically involve?

- A: It’s crucial for identifying potential mechanical issues or safety hazards before operation. It typically involves checking tires, brakes, steering, hydraulics, forks, mast, lights, horn, battery/fuel, fluid levels, and controls.

- Q: Describe the correct procedure for picking up a palletized load.

- A: Approach squarely, level forks, ensure forks are spread correctly and fully inserted under the load, tilt mast back slightly (if applicable), lift the load clear of the floor, retract the mast, and then lower the load to the lowest safe travel height.

- Q: What is the safe operating speed for a reach truck in a warehouse?

- A: A safe operating speed is one that allows the operator to stop safely in an emergency, considering factors like floor conditions, visibility, pedestrian traffic, and the load being carried. It’s typically a walking pace in pedestrian areas.

- Q: What are the rules regarding pedestrians and forklifts in a shared environment?

- A: Pedestrians always have the right of way. Operators must yield to pedestrians, maintain a safe distance, use the horn at blind spots, and make eye contact. Pedestrians should be aware of forklift routes and designated walkways.

D. Stability & Load Handling

- Q: Explain the "stability triangle" or "stability pyramid" concept.

- A: This concept illustrates the area within which a forklift’s center of gravity must remain to prevent tip-over. For a reach truck, it’s typically a pyramid formed by the three points of suspension (front wheels/outriggers and the rear steer wheel). Understanding this helps in safe load handling and maneuvering.

- Q: What factors can negatively affect a reach truck’s stability?

- A: Exceeding load capacity, uneven loads, high lifts, sudden braking or acceleration, sharp turns, uneven surfaces, worn tires, and improper mast tilt can all compromise stability.

- Q: What should you do if a load feels unstable after picking it up?

- A: Immediately lower the load to the lowest safe travel height, retract the mast, and re-evaluate the load’s placement and stability. Do not attempt to travel with an unstable load. Re-stack or re-position if necessary.

E. Emergency Procedures

- Q: What is the first action an operator should take in the event of a reach truck tip-over?

- A: Stay in the operator’s compartment, grip the steering wheel firmly, brace your feet, and lean in the opposite direction of the tip-over. Do NOT attempt to jump out.

- Q: What steps should be taken if you are involved in or witness an accident involving a reach truck?

- A: Secure the scene, ensure the safety of all personnel, administer first aid if necessary, notify a supervisor immediately, and do not move the truck or load until authorized. Cooperate fully with the investigation.

Key Elements of the Practical Test (Maneuvering & Handling)

The practical test evaluates your ability to apply theoretical knowledge in real-world scenarios. Assessors will look for:

- Thorough Pre-Shift Inspection: Demonstrating a systematic check of all critical components.

- Safe Mounting/Dismounting: Proper use of handholds and three points of contact.

- Smooth and Controlled Operation: Gradual acceleration, controlled braking, and precise steering.

- Maneuvering in Tight Spaces: Navigating forward and reverse through cones or simulated aisles without contact.

- Accurate Load Pickup and Placement: Selecting, lifting, and placing loads smoothly and accurately at various heights and in narrow racking, ensuring stability.

- Load Stability Checks: Visually assessing the load’s stability before and during movement.

- Situational Awareness: Constantly scanning surroundings for pedestrians, other equipment, and obstacles.

- Proper Parking and Shutdown: Parking in designated areas, lowering forks, engaging the brake, and turning off the power.

Tips for Success in the Practical Test:

- Slow and Steady Wins the Race: Don’t rush. Precision and control are more important than speed.

- Look Where You’re Going: Always look in the direction of travel, and utilize mirrors effectively.

- Maintain Clearances: Be mindful of the truck’s dimensions and the load’s footprint.

- Communicate: Use the horn at intersections and blind spots.

- Visualize: Plan your movements before executing them.

Practical Advice for Test Preparation

- Study the Operator’s Manual: This is your primary resource for understanding your specific reach truck model.

- Practice Under Supervision: Gain as much hands-on experience as possible with a certified instructor. Repetition builds muscle memory and confidence.

- Understand Load Charts: Learn how to read and interpret the truck’s load capacity chart for different lift heights and load centers.

- Prioritize Safety: Always put safety first. This mindset will guide your answers and actions.

- Simulate Test Conditions: If possible, practice in an environment that mimics the test area.

- Get Adequate Rest: A well-rested mind performs better under pressure.

Overcoming Challenges in Reach Truck Operation

Reach trucks, while efficient, present unique operational challenges:

- Limited Visibility: High loads or reaching into deep racking can obstruct views.

- Solution: Use mirrors, turn your head to look in the direction of travel, use spotting assistance if available, and always proceed slowly.

- Narrow Aisles: The primary benefit is also a challenge, demanding precise steering.

- Solution: Practice smooth, controlled turns, understand your truck’s turning radius, and ensure adequate clearance.

- High Lifts: Placing or retrieving loads at extreme heights requires immense precision and attention to stability.

- Solution: Approach slowly, ensure the mast is vertical, watch for sway, and never travel with elevated loads.

- Uneven Loads/Floors: Can compromise stability significantly.

- Solution: Inspect loads for stability before lifting, adjust the load if necessary, and report uneven floor surfaces.

- Battery Management: Electric reach trucks require proper battery charging and maintenance.

- Solution: Follow manufacturer guidelines for charging, watering, and cleaning batteries to ensure longevity and prevent hazards.

Concluding Summary

Mastering the reach truck test is more than just passing an exam; it’s about acquiring the knowledge and skills necessary to operate a powerful piece of machinery safely and efficiently. By thoroughly understanding the theoretical principles, practicing diligently, and always prioritizing safety, you not only ensure your own well-being but also contribute to a safer and more productive work environment. A certified reach truck operator is a highly valuable asset, capable of maximizing warehouse efficiency while minimizing risks.

Training & Certification Cost Guide

Please note: Prices are estimates and can vary significantly based on location, provider, course duration, and whether training is on-site or off-site.

| Service/Item | Description | Typical Cost Range (USD) | Notes |

|---|---|---|---|

| Basic Operator Training | Full course for new operators, including theory and practical sessions. | $300 – $700 per person | Often 1-3 days. May offer group discounts. Includes test fees. |

| Refresher/Recertification | Shorter course for already certified operators needing renewal (every 3 yrs). | $150 – $350 per person | Typically 0.5 – 1 day. Focuses on updates and practical refreshers. |

| On-Site Training | Instructor comes to your facility using your equipment. | $1000 – $2500 per day | Cost is per day/group, not per person. Ideal for companies training multiple employees. Excludes travel fees. |

| Written Test Fee (Stand-alone) | For theory test only, if offered separately. | $50 – $100 | Rare to be separate; usually included in training packages. |

| Practical Test Fee (Stand-alone) | For hands-on operating assessment only. | $75 – $150 | Also rarely separate. |

| Combined Certification | Includes both theory and practical exams as part of a complete course. | Included in training | Most common approach; ensures comprehensive assessment. |

| Online Theory Course | Self-paced online learning for theoretical knowledge. | $50 – $150 | Often requires a separate practical assessment by a certified trainer for full certification. Not a standalone certification. |

Frequently Asked Questions (FAQ)

Q1: How long is reach truck certification valid?

A: In most regions (e.g., OSHA in the US, HSE in the UK), reach truck operator certification is valid for three years. After this period, a refresher course and re-evaluation are required.

Q2: Can I operate other types of forklifts with a reach truck license?

A: No. Certification is specific to the class and type of powered industrial truck. While some principles are transferable, operating a different type (e.g., a counterbalance forklift or an order picker) requires specific training and certification for that equipment.

Q3: What’s the main difference between a reach truck and a counterbalance forklift?

A: A counterbalance forklift uses a weight in the rear to offset the load in the front. A reach truck uses forward-extending outriggers and a "reach" mechanism to extend the forks beyond the outriggers, allowing it to work in much narrower aisles and often lift to greater heights.

Q4: What happens if I fail the reach truck test?

A: If you fail the test (either written or practical), you will typically be given an opportunity to retake it after receiving additional training or practice. The training provider will advise on the specific re-test policy and any associated fees.

Q5: Where can I find accredited training providers for reach truck certification?

A: You can find accredited providers through industry associations (e.g., Material Handling Industry, ITA), local community colleges, vocational schools, or by searching online for "forklift training" or "reach truck certification" in your area. Always verify their accreditation and reputation.

Q6: Is online training sufficient for reach truck certification?

A: Online training can be excellent for the theoretical (written) portion of the certification. However, practical, hands-on training and evaluation by a certified instructor are always required to achieve full, valid reach truck operator certification. Online-only training is not sufficient for operating heavy machinery.